Large-scale construction projects combine hundreds of suppliers, multiple trades and constantly shifting site conditions. Materials and equipment must arrive exactly when they’re needed; a single late delivery can create cascading delays that affect several teams. Moreover, the sector faces persistent labor shortages, schedule disruptions and cost overruns due to late materials, unexpected site conditions and weather impacts. Logistics managers must balance quality and cost while ensuring that projects stay on track.

Plan for complexity and build buffers

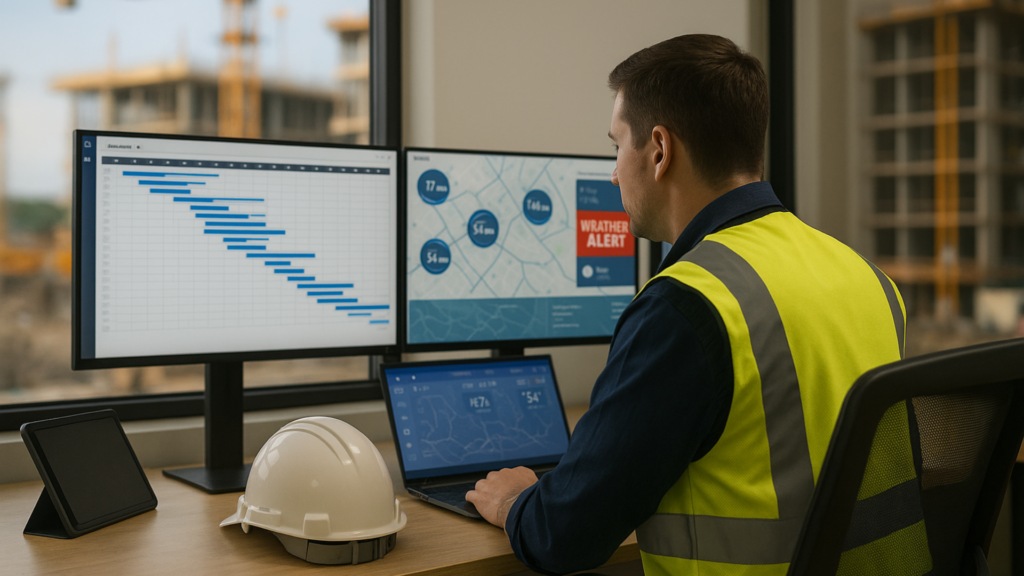

Unlike standard manufacturing, construction sites evolve over time. To avoid downtime when deliveries are delayed, build buffer time into your schedules and identify critical path items in advance. Real-time tracking and early-warning systems enable supply chain teams to get proactive alerts about late materials. When potential delays are identified, your logistics partner should help you adjust schedules or arrange alternative transportation before the timeline slips.

Optimize routes and consolidate shipments

Transportation costs for construction materials can fluctuate due to fuel price volatility and capacity constraints. One way to manage costs is to optimize load planning and choose routes carefully (https://www.dtsone.com/challenges-in-food-and-beverage-logistics/). Consolidate shipments when possible to maximize trailer space and negotiate contracts that provide cost consistency across key lanes. Buffering schedules also helps reduce the need for expensive expedited shipments. For heavy or oversize loads, ensure your carrier has the right equipment and permits to prevent last-minute delays.

Strengthen collaboration across the supply chain

Cascading delays often stem from poor communication between procurement, logistics and on-site teams. Establish clear channels for sharing project schedules, change orders and delivery updates. Partnering with a logistics provider that offers end-to-end visibility and responsive customer service reduces the risk of surprises. When weather, traffic or labor issues cause delays, having a provider that can quickly tap into a wide carrier network and switch to alternative modes—such as flatbeds, drop trailers or even expedited services—keeps materials moving

How Go To Truckers supports construction logistics

Go To Truckers understands the complexity of construction supply chains. Our team works closely with project managers to map delivery schedules and establish buffer periods. With real-time tracking and early-warning alerts, we help you foresee disruptions before they become costly setbacks. Our nationwide network includes flatbeds, drop-deck trailers and specialized carriers that can handle heavy materials and machinery, and we vet each partner for reliability and compliance. By combining consolidated loads, negotiated rate structures and route optimization, we keep transportation costs predictable without sacrificing service quality. From sourcing last-minute concrete loads to coordinating multi-stop deliveries of lumber, Go To Truckers ensures your materials arrive on time, so your project stays on schedule and on budget.

No Comments yet!